I have that unmistakable EV grin on since Sunday :)

Friday, August 1, 2014

Lift-off.......!

Labels:

A123 cells,

AC31,

Alternative Energy,

Citroen,

Citroen DS,

Curtis,

DS,

Elcon,

Electric Vehicle,

EV,

HPEVS,

Hybrid,

K2 Energy,

LP26650EV,

MiEV,

Prius,

Sustainability,

Sustainable,

Tesla,

Volt

Monday, May 12, 2014

A year ago tomorrow; the ICE engine came out!

As final builds go, this one is painstakingly slow!

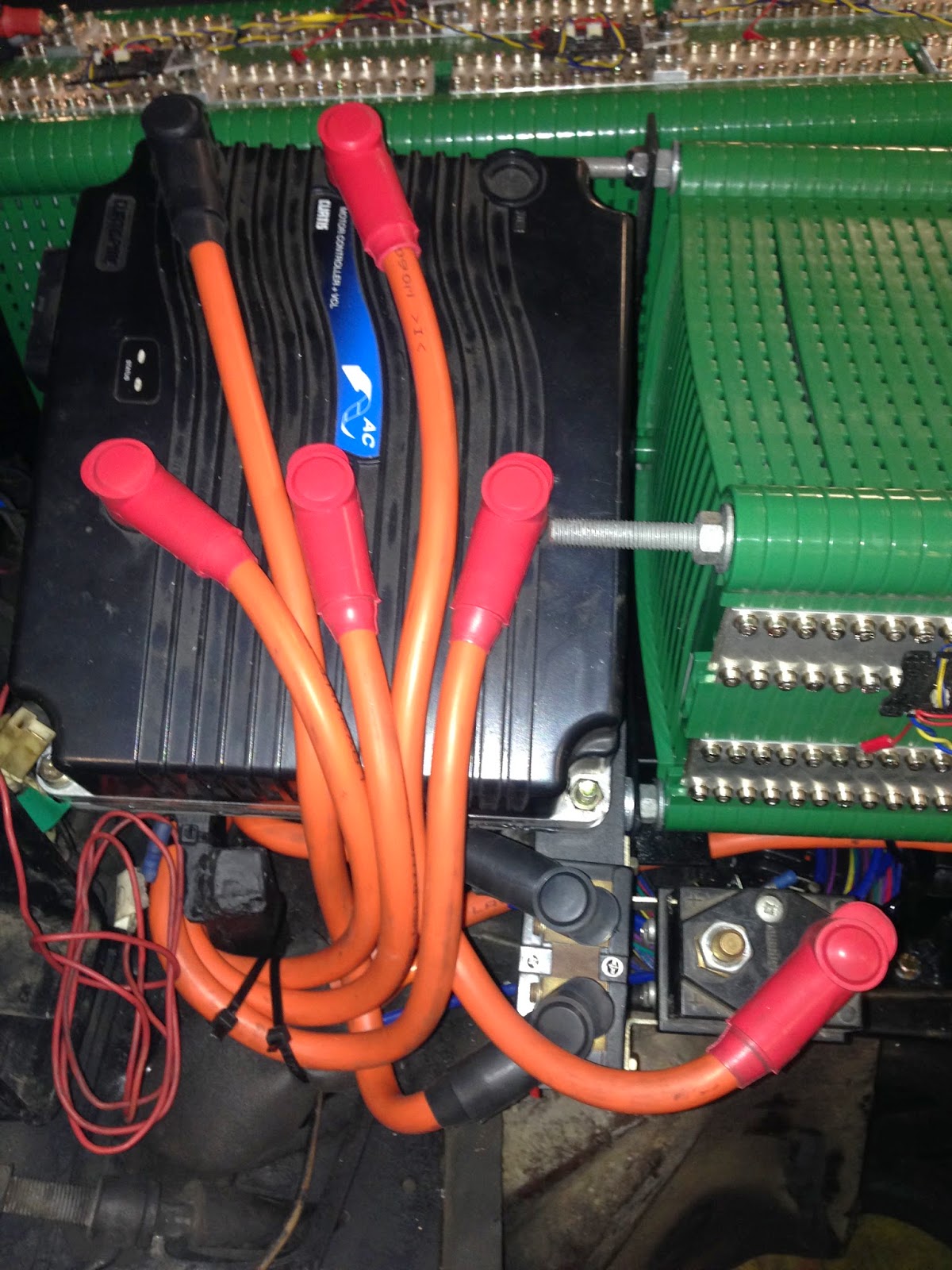

All 96v cabling is done. Most of the BMS wiring is finished.

Above one can see the controller wired-in and having received the pin-outs for throttle and regen brake hall-effect pots, they are minutes away from being finished too :)

We still need to wire-up the charging circuit, although all the elements are now in place as you can see below.

Under the bonnet is now covered with factory original padding (apart from the bit at the front which is usually uncovered:

Oh, the 2 black strips above (on the bonnet ribs) are my new LED under-bonnet lights. And now for the icing on the cake, I am so happy with the result of the regen brake over the original Citroen DS "mushroom" brake. The theory is that standard braking will be taken-care of by the regen brake and in emergencies or immediate stop requirements, pushing the brake further, activates the very positive DS disk brakes.

Look Ma, clutch gone..... Yes, where the clutch pedal used to be, now is a space where one may comfortably rest the left foot. And for those of you with a keen eye, you may see that the clutch pedal is still in fact there, behind the carpet.

Oh! almost forgot……. One cannot forget the reverse switch. Here it is that red "safety" switch to the left of the steering wheel in the pic above.

And one last thing, the impact sensor, now mounted and ready for wiring, in the pic below.

All 96v cabling is done. Most of the BMS wiring is finished.

Above one can see the controller wired-in and having received the pin-outs for throttle and regen brake hall-effect pots, they are minutes away from being finished too :)

We still need to wire-up the charging circuit, although all the elements are now in place as you can see below.

Right at the front is the Elcon Charger, in front of a bank of cells in the green Joeys and behind that (in front of the rest of the green Joeys, are 2 x 12v batteries, flanked by 2 x 12v DCDC converters. Why 2 x 12v batteries. Well, the motor that now drives the hydraulic system in the DS EV is a 24v motor. It cuts in and out as required to top-up system. So, when the car is running as usual, the batteries are in parallel, providing the required 12v for the car electrics. However, when the pressure-switch cuts-in and gets the 24v motor going, solenoids (high-current relays), switch the batteries to in-series mode still allowing 12v to flow to the car electrics and 24v for the hydraulic compressor motor.Oh, the second DCDC converter is a backup and privides symmetry......

A "tray is being constructed that will protect the BMS's on top of the front cell range with a backing plate. This "tray" will be the space for a charging cable as well as other odds and ends.

The "tray" you see below is version 1 which has been scrapped while we produce a replacement.

Under the bonnet is now covered with factory original padding (apart from the bit at the front which is usually uncovered:

|

| Sorry.... Cannot seem to be able to rotate pic! |

Look Ma, clutch gone..... Yes, where the clutch pedal used to be, now is a space where one may comfortably rest the left foot. And for those of you with a keen eye, you may see that the clutch pedal is still in fact there, behind the carpet.

Oh! almost forgot……. One cannot forget the reverse switch. Here it is that red "safety" switch to the left of the steering wheel in the pic above.

And one last thing, the impact sensor, now mounted and ready for wiring, in the pic below.

Labels:

A123 cells,

AC31,

Alternative Energy,

Citroen,

Citroen DS,

Curtis,

DS,

Elcon,

Electric Vehicle,

EV,

HPEVS,

Hybrid,

K2 Energy,

LP26650EV,

MiEV,

Prius,

Sustainability,

Sustainable,

Tesla,

Volt

Thursday, May 1, 2014

Final Build - more pics

Enjoy!

My EV mates advising me and checking-on progress, over a pizza and watching Das Auto video.......

|

| Notice Emergency Power Breaker, bottom-right |

|

| Another view |

|

| No, I do not like that colour either! |

|

| Good view of the Shunt and Contactor |

|

| Another View |

Labels:

A123 cells,

AC31,

Alternative Energy,

Citroen,

Citroen DS,

Curtis,

DS,

Elcon,

Electric Vehicle,

EV,

HPEVS,

Hybrid,

K2 Energy,

LP26650EV,

MiEV,

Prius,

Sustainability,

Sustainable,

Tesla,

Volt

Tuesday, April 29, 2014

Final Build

Yes, plenty of progress since our last post. After a grueling Christmas/new year period constantly at it, we had to take a break from the project, recharge our energies (as-in human energies) before we could launch into the final build.

It was "fun" taking the Hydraulic Pump (that drives suspension, brakes and power steering in a Citroen DS) off the ICE and adapting it for an electric motor that now drives the Hydropneumatic system!

Well a bit of detail! We are utilising a 24v x 450w x 400 RPM bicycle motor to drive the pump (as kindly recommended by Henk the only other Citroen DS conversion I know off; in Holland). The previous motor I had acquired from China did not work as it was not geared; high-revving with no low-end torque. My friend Geoff machined pulleys for me an supplied a rubber toothed belt that now drives the pump off the motor.

Joey sample assembly

All 360 batteries that give us 240Ah @ 96v, are now assembled and mounted in the vehicle, mostly up-front on top of the motor and some in the place where the fuel tank used to reside. This gives optimal weight distribution and overall weight that matches that of the original vehicle. And what a sight it is.........

|

| "Petrol Tank" Batteries |

|

| First 2 sets of Batteries mounted |

|

| First 3 sets of Batteries mounted with Controller |

|

| Notice the redirected Gear Lever Mechanism, now underneath the Batteries |

|

| The (all so important) accumulator re-position from the old ICE |

|

| The Hall-Effect Throttle |

|

| Wiring the Controller and Contactor |

|

| Curtis Controller |

|

| Another view of the Controller |

Citroen does not use a traditional foot brake. Instead it utilises a "mushroom" similar to the old dimmer switches in old cars for those of us old enough to remember. In any case, it is a small mound on the floor that you merely squeeze millimetrically with your foot to generate amazing braking power. We have placed a hall-effect "throttle" pedal over the top of the "mushroom so that now the firs 75% of the travel is braking utilising regen to slow down the vehicle with the "mushroom" available just by moving the pedal further to activate the disk brakes for positive and aggressive braking requirements, hopefully only on rare occasions. All other times, braking is recharging the batteries.

This theory remains to be tested in practice. Now off to do some more cabling............... Stay tuned!

Labels:

A123 cells,

AC31,

Alternative Energy,

Citroen,

Citroen DS,

Curtis,

DS,

Elcon,

Electric Vehicle,

EV,

HPEVS,

Hybrid,

K2 Energy,

LP26650EV,

MiEV,

Prius,

Sustainability,

Sustainable,

Tesla,

Volt

Friday, February 7, 2014

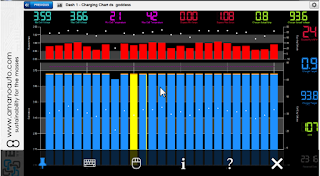

More Pictures - Charging Progress

Labels:

A123 cells,

AC31,

Alternative Energy,

Citroen,

Citroen DS,

Curtis,

DS,

Elcon,

Electric Vehicle,

EV,

HPEVS,

Hybrid,

K2 Energy,

LP26650EV,

MiEV,

Prius,

Sustainability,

Sustainable,

Tesla,

Volt

Wednesday, February 5, 2014

A Picture tells a Thousand Words

Well, a lot of progress. The devil is in the detail. All is now manufactured and what remains is the final rebuild, battery pre-charging and wiring.........

Less words and more pics to show progress.

The batteries in assembly:

Using the easy-to-build, green Joey A123 pouch holders and connectors.

Less words and more pics to show progress.

The batteries in assembly:

Using the easy-to-build, green Joey A123 pouch holders and connectors.

Jaron and Mark installing the BMS:

Thank you guys.

The lights are flashing..... We have lift-off!

If you look closely you will see lights flashing in the first part of the video.

We've also received the regen brake pedal

It is no news to Citroen DS lovers that the DS does not have a brake pedal. Instead, it has a "mushroom" button, that DS owners know to thread on gently, as the movement required to go from no brakes to full lock-up is millimetric!

So we are introducing a brake pedal into our Electric DS. Why? Well, we have regen with our AC motor/controller combination. We shall utilise the pedal in the picture (originally manufactured as a throttle for EV deployment) to engage regen braking. The pedal will be setup so that when aggressive braking is required, the pedal pushes the "mushroom" as the pedal is pushed all the way.

This creates progressive braking that starts with, and mostly uses, regen and engages the powerful DS brakes if and when required. We believe that, with some level of precise setting, this will make for ideal braking with little usage of the disc brakes.

Labels:

A123 cells,

AC31,

Alternative Energy,

Citroen,

Citroen DS,

Curtis,

DS,

Elcon,

Electric Vehicle,

EV,

HPEVS,

Hybrid,

K2 Energy,

LP26650EV,

MiEV,

Prius,

Sustainability,

Sustainable,

Tesla,

Volt

Friday, January 3, 2014

Preparing for the BIG unveiling........

And you, my BLOG reader get the first look-in!

New number plates ready.... yay!

Stay tuned....................

New number plates ready.... yay!

Many hours of work left. The vehicle is now fully-assembled as an EV (excluding wiring and BMS). However, this was done as an exercise of dimensioning (is there such a word?) everything. All the battery trays (Joey) are in (sans batteries) and all the various and many related components mounted in their right places. Here is the final mini project, Getting the hydraulic pump to work off an electric motor.

This is currently the Achilles Heel of the project for a number of reasons. Our motor is 12 volt 500w. Might be underpowered. Also, it is mounted laterally to the pump, driven by 2 belts. This might place too much lateral pressure on the bearing. We are going to test as is, as we wanted to utilise the original components (hydraulic pump). However, as my Citroen Expert Jason recommended, we might go to a CX pump which has a layout where I can connect the motor radially, easing pressure off the bearings.

Should all that fail, we shall resort to replacing the pump/motor assembly with a prepackaged electric pump as utilised in certain vehicles (we have already secured one). This would take a bit more engineering.

However, for now, as I said earlier, there remain MANY hours of work and we are truing to meet a January 31st deadline. What's there to do........?

Well, everything has to be disassembled. All the welded assemblies need to be finished-off, ground down and painted. The gearbox/motor assembly needs to be tightened and greased-up. Then the process of final assembly starts. All needs to go back in methodically, connecting the drive shafts, the hydraulics and wiring the whole vehicle (not a minor feat).

Oh, and we have to assemble and connect 360 batteries! Hours of brain-numbing work.

Once that's all done-up, and a few rust spots and scrapes cleaned-up, then the process of setting up the AC mpotor/controller and BMS starts. This "should" be quite straight-forward; but we have learnt that the devil is always in the detail.

Stay tuned....................

Labels:

A123 cells,

AC31,

Alternative Energy,

Citroen,

Citroen DS,

Curtis,

DS,

Elcon,

Electric Vehicle,

EV,

HPEVS,

Hybrid,

K2 Energy,

LP26650EV,

MiEV,

Prius,

Sustainability,

Sustainable,

Tesla,

Volt

Subscribe to:

Posts (Atom)